The cavernous factory floor of the future is eerily quiet. No rumbling machinery or bustling workers. Just silent robots meticulously assembling products with inhuman precision.

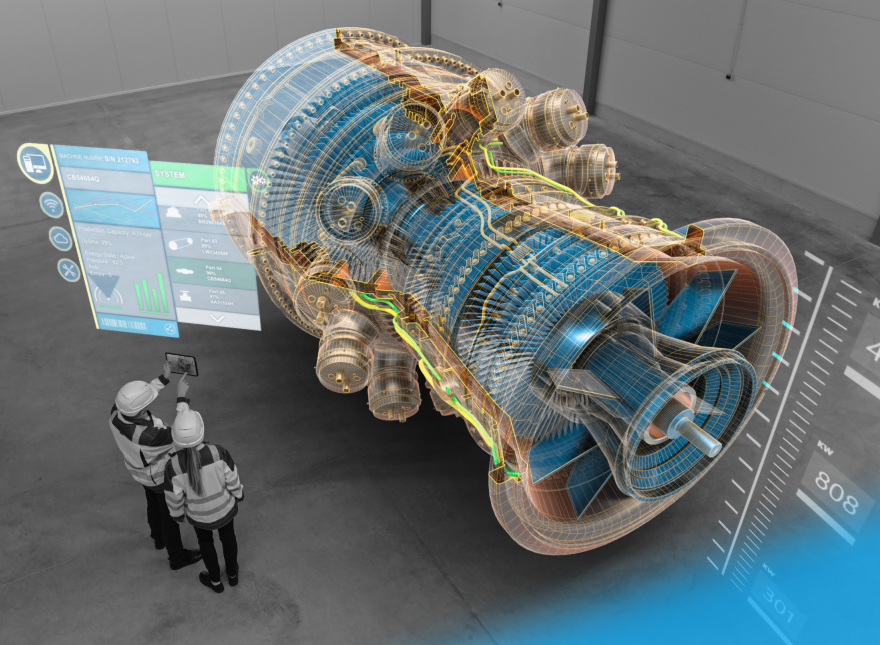

This is the vision of the “virtual factory” - a futuristic manufacturing concept powered by artificial intelligence, automation and big data. It may sound like science fiction, but virtual factories are already emerging across Europe.

At Philips' electric shaver plant in the Netherlands, the company is testing a “digital twin” system where virtual models simulate the real production lines in perfect detail. Engineers can troubleshoot issues and reconfigure processes in the virtual world before implementing changes, saving significant time and money.

Meanwhile, automakers like Audi have used virtual simulations to slash vehicle development cycles by years. Aerospace giant Airbus is digitally modelling the assembly of entire planes across European factories, coordinating global production like an orchestral conductor.

The virtual factory is the factory of the future, according to Dr. Lai Xu, an expert in digital manufacturing at Bournemouth University in the U.K. “The customised shoe can be designed elsewhere but made locally, resulting in a more efficient and flexible manufacturing process and with less environmental impact,” Xu said.

The Digital Lifeline

Europe has long struggled to compete with overseas manufacturing industries that use cheap labour and lax regulations. Its factories and industrial base shrank over decades as production shifted to Asia.

But the virtual factory could provide a lifeline. By harnessing automation, simulations, and real-time data analytics, European factories can become lean, flexible and hyper-efficient. Costs plummet, while the ability to customise products blows up.

“Virtual factories allow you to manufacture a pair of customised shoes designed in Milan and made anywhere in the world,” says Xu.

For policymakers desperate to revive European manufacturing and create jobs, the promise of virtual factories is irresistible.

The E.U. has now embraced the technology as critical for building its “industrial competitiveness” against rivals like the U.S. and China.

The Commission recently called virtual factories “fundamental” to Europe’s plans for a “new industrial revolution”. It aims to have 90% of EU manufacturers use digital technologies by 2030. While virtual factories promise benefits like reduced costs, increased efficiency and flexibility, the transition will be challenging for many European companies, particularly small and medium enterprises. Only about 20% of European companies currently use digital technologies in an advanced way.

The Coming Revolution

Yet fulfilling the grand vision of virtual factories won't be easy. European companies must digitise legacy production lines, upskill workers for a new industrial era, and invest heavily in emerging technologies.

For giants like Airbus, Audi or Philips, the shift is underway. But for the over 95% of European firms that are SMEs, transforming into a hyperconnected, data-driven factory is daunting.

“This requires a change in management and skills development,” says Dr. Cécile Girardot, who coordinates E.U. efforts to support SMEs with virtual factory technologies.

Yet the writing is on the wall. As virtual factory technologies mature, their potential to reshape European manufacturing grows.

One day, robots may construct entirely customised products on-demand using 3D printing blueprints beamed from around the world. AI systems will monitor all operations and optimise them instantly. Whole new business models will emerge.

It’s a future both exhilarating and frightening. While virtual factories could restore Europe’s industrial might and create high-tech jobs, they also threaten mass unemployment as machines replace human hands.

Policymakers will have to implement protections for those displaced even as they encourage the march towards virtualized production. Europe's factory workers will need assistance transitioning into the digital future.

The coming revolution will be hugely disruptive. But if Europe can re skill workers and help companies adapt, virtual factories may just power a new industrial age on the continent. One where manufacturers large and small can thrive once again.